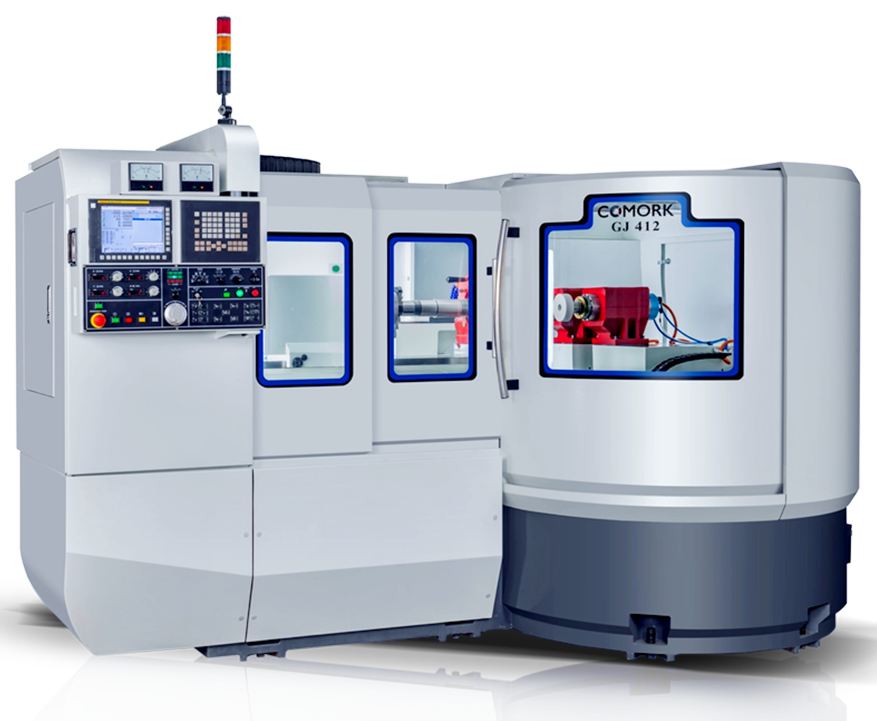

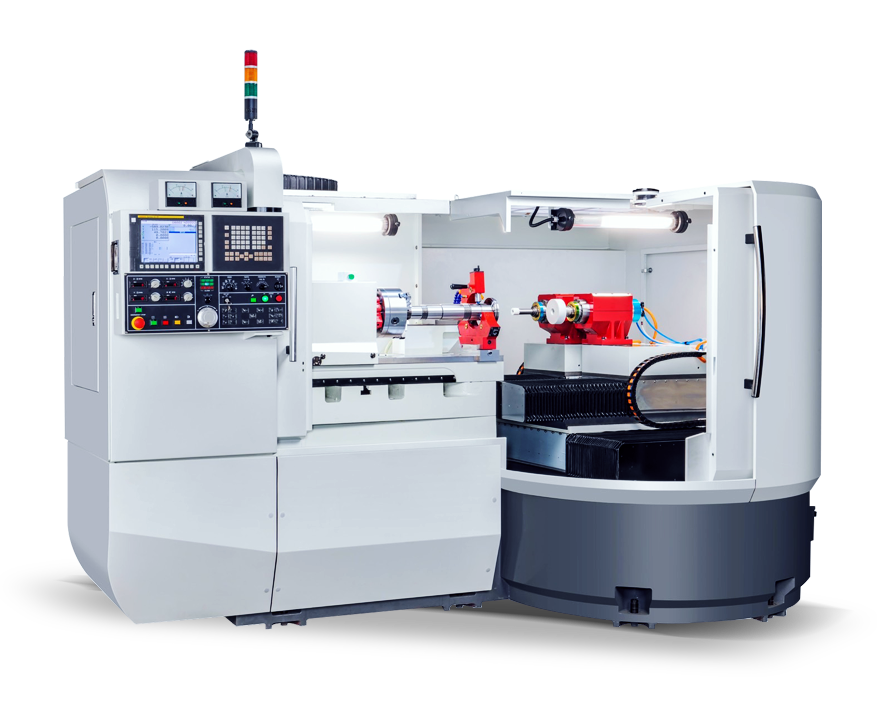

CNC External Internal Grinding Machine Features

One of the standout features of this external internal grinding machine is its spindle plane, which can be manually adjusted (B Axis) from 0˚ to 15˚. This adjustment capability enhances the flexibility of the machine, making it suitable for complex grinding tasks.

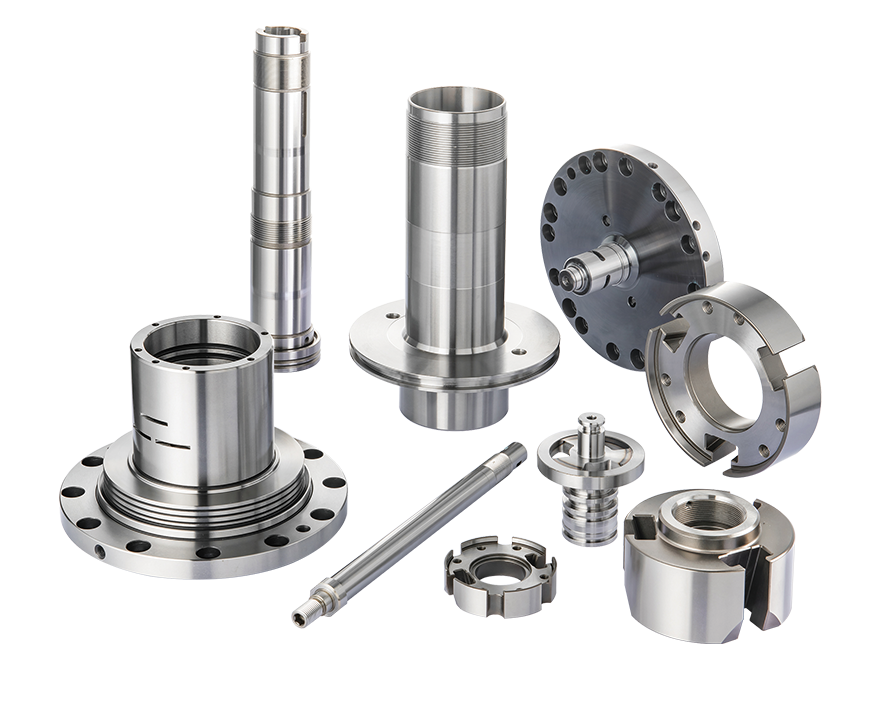

The CNC external internal grinder is capable of internal diameter processing within a scope of 0 to 300 mm and can grind external diameter diameters up to ¢360 mm with a maximum grinding length of ¢300 mm. In terms of load capacity can handle workpieces weighing up to 120 kg. GJ-412 CNC external internal grinding machine can process up to eight faces in one cycle, improving efficiency and reducing production time.

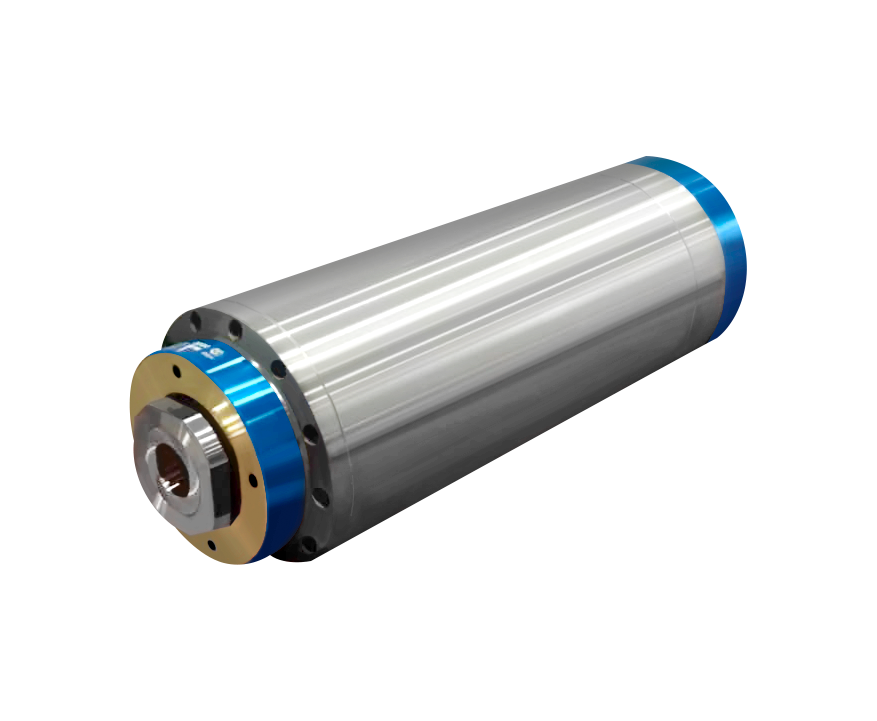

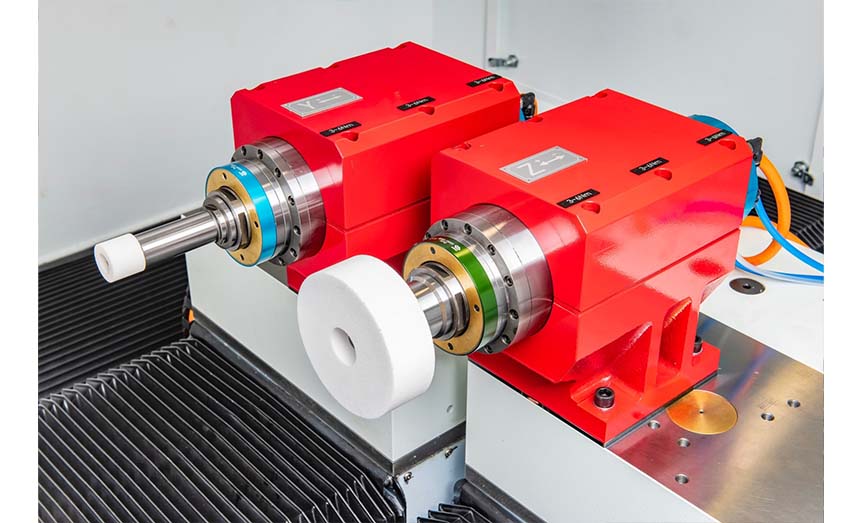

- Standard equipped with an embedded spindle, with a wide range of applicable speeds and higher cutting ratios, to achieve maximum grinding efficiency.

- Internal diameter, external diameter, end face, and inclined surface grinding can be completed in one step.

- X, Y, Z axes are all equipped with high-precision linear guides.

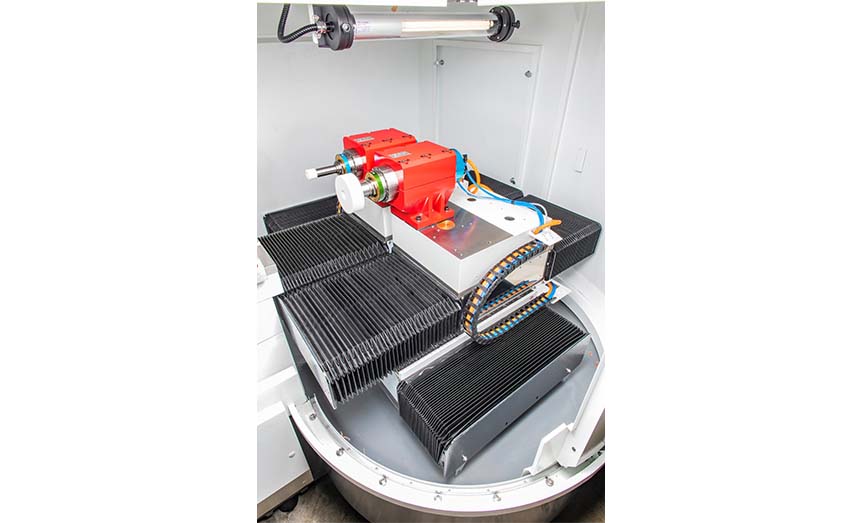

- Dual grinding wheel spindle structure, demonstrating high-efficiency internal/external diameter grinding.

- B-axis combined with a ring optical encoder, achieving optimal precision in rotational positioning.

- Multi-surface grinding requires only one clamping of the workpiece.

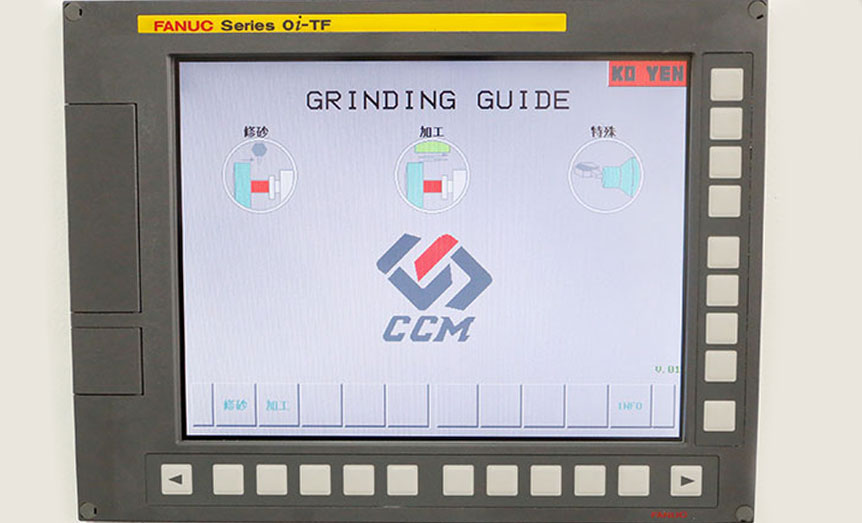

- Equipped with FANUC 0i-TF CNC controller.

- Non-circular grinding function (optional).

- Base designed with the user in mind, featuring a semi-circular design to reduce space wastage, along with a thick,stable, and high-rigidity machine body structure to ensure optimal grinding stability.

- Fully enclosed guard.

Machine Specifications

| CATEORGY | GJ-412-500 | GJ-412-1000 |

|---|---|---|

| Maximum Workpiece Diameter | Ø 450 mm | |

| Workhead Revolve Speed | 0 ~ 1,000 rpm | |

| Spindle Plane Manual Angle Adjust (B Axis) | 0˚ ~ 15˚ | |

| ID Processing Scope | 0 ~ 300 mm | |

| Maximum Grinding Outer Diameter Range | ¢360 mm | |

| Maximum Grinding Length | ¢300 mm | |

| Maximum Workpiece Length | 1,000 mm | |

| Maximum Number of Faces Processed in One Cycle | 8 | |

| Load Capacity of Workpiece | 120 KG | |

| Maximum Travel of X-axis | 550 mm | |

| Maximum Travel of Y-axis | 375 mm | |

| Maximum Travel of Z-axis | 375 mm | |

| X-axis Travel Speed | 0 ~ 10,000 mm/min | |

| Y-axis Travel Speed | 0 ~ 10,000 mm/min | |

| Z-axis Travel Speed | 0 ~ 10,000 mm/min | |

| Minimum Travel Unit of X-axis | 0.0001 mm | |

| Minimum Travel Speed of Y-axis | 0.0001 mm | |

| Minimum Travel Unit of Z-axis | 0.0001 mm | |

| Spindle Motor for X-axis Clamp | Servo Motor 1.2KW | |

| Power Demand | 20 kW | |

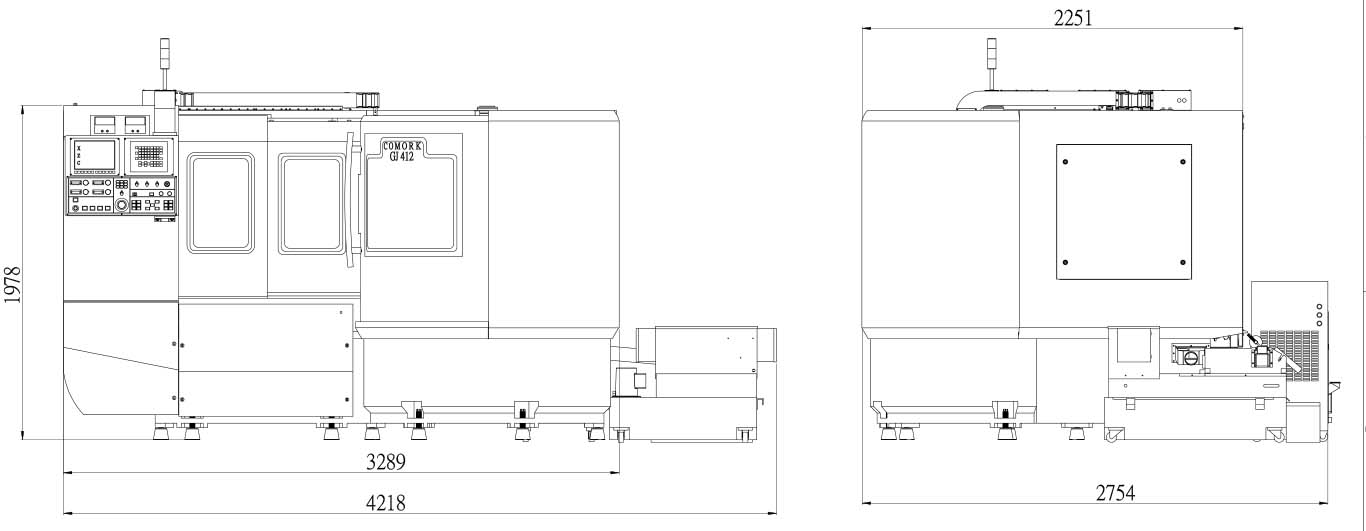

| Mechanical Dimensions | 2754*3289*1978 mm | |

| Machine Net Weight | 9,500 Kg |

Machine Measurement