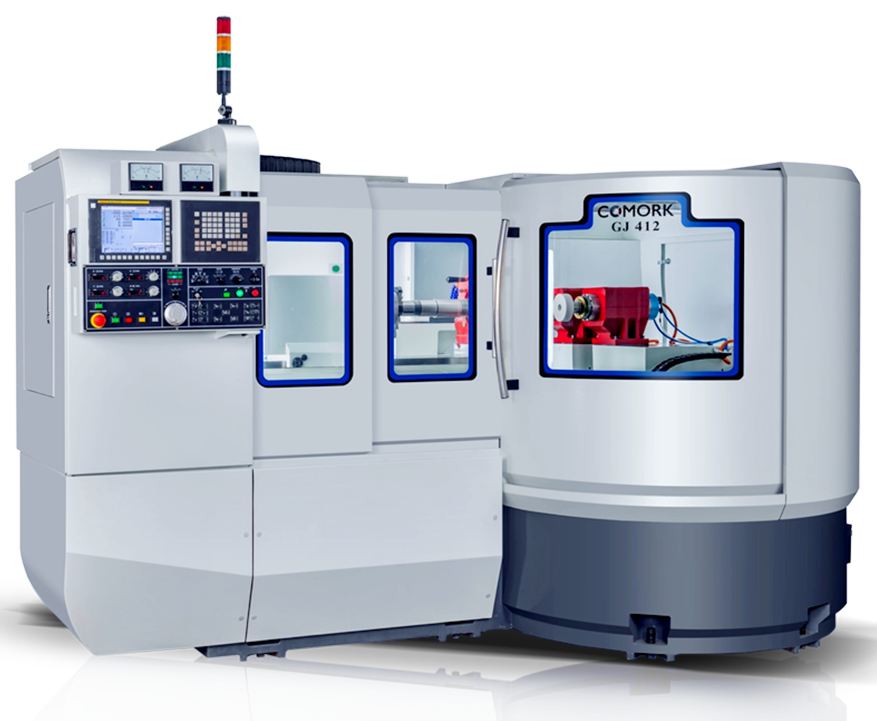

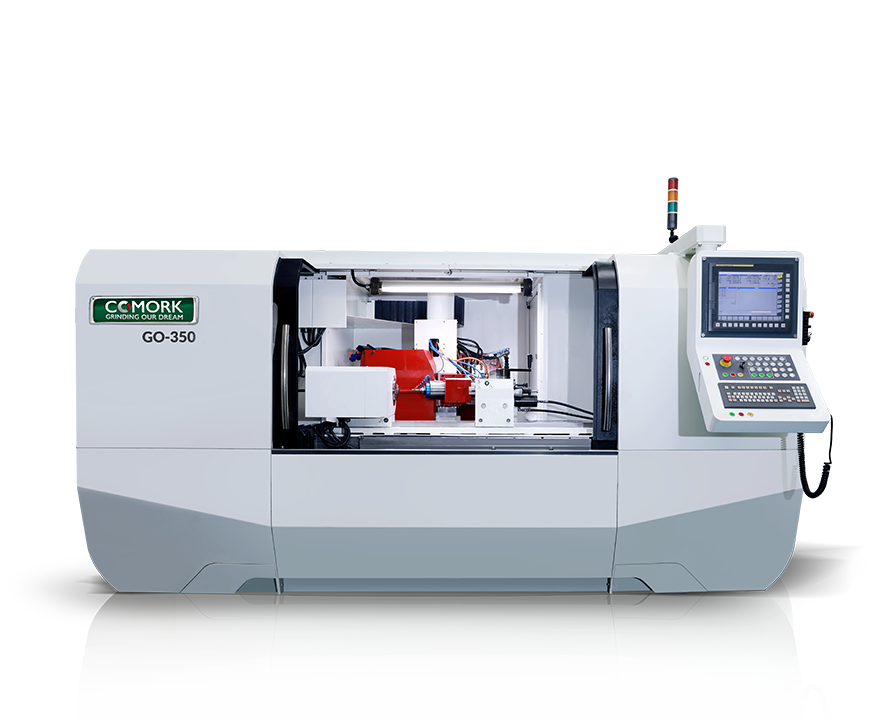

CNC ID/OD Grinding Machine Feature

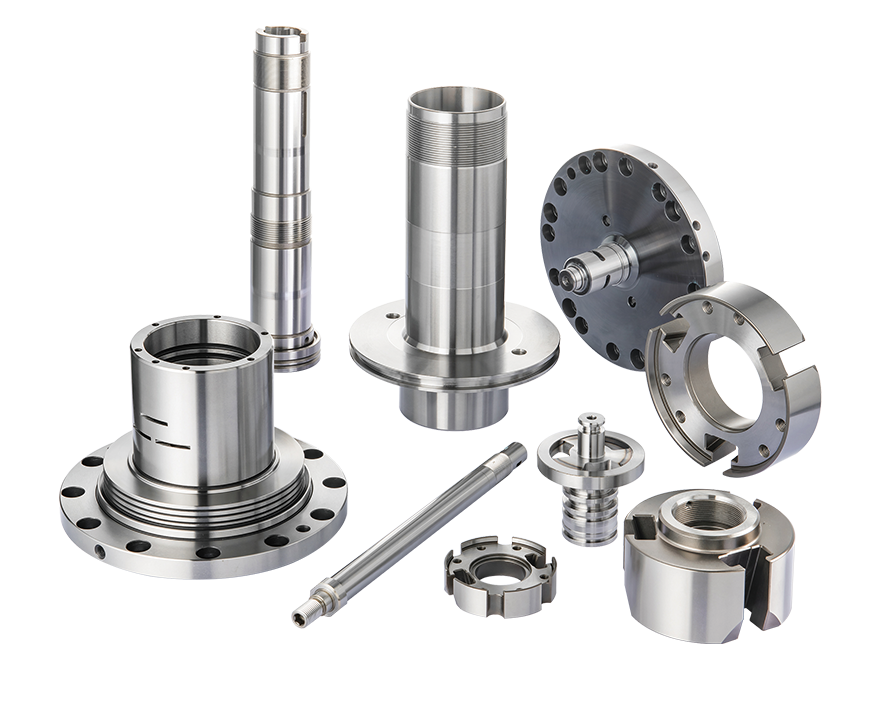

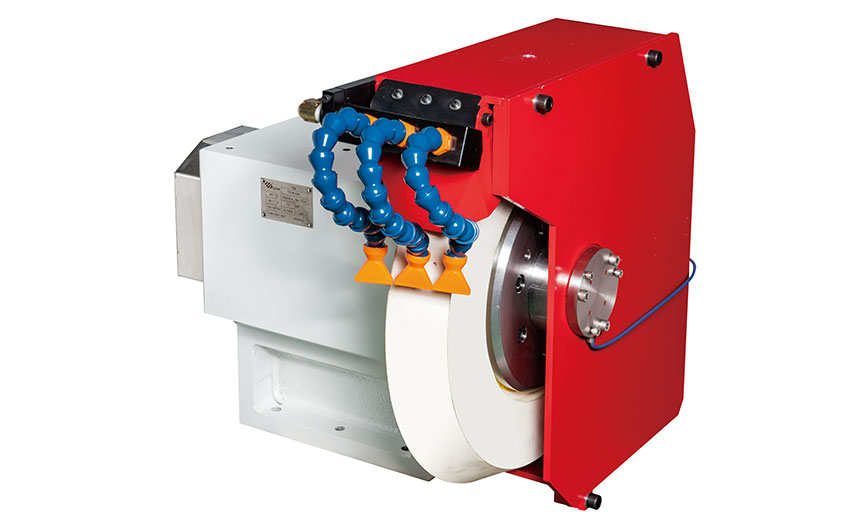

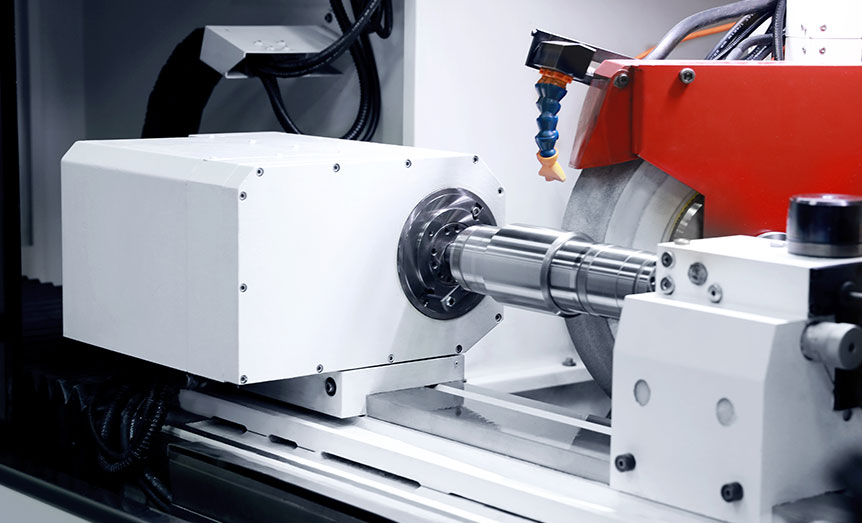

- Turret Wheelhead: Equipped with G1 (OD), G2 (OD), and G3 (ID) for complex workpieces, simplifying the processing program and enhancing equipment utility.

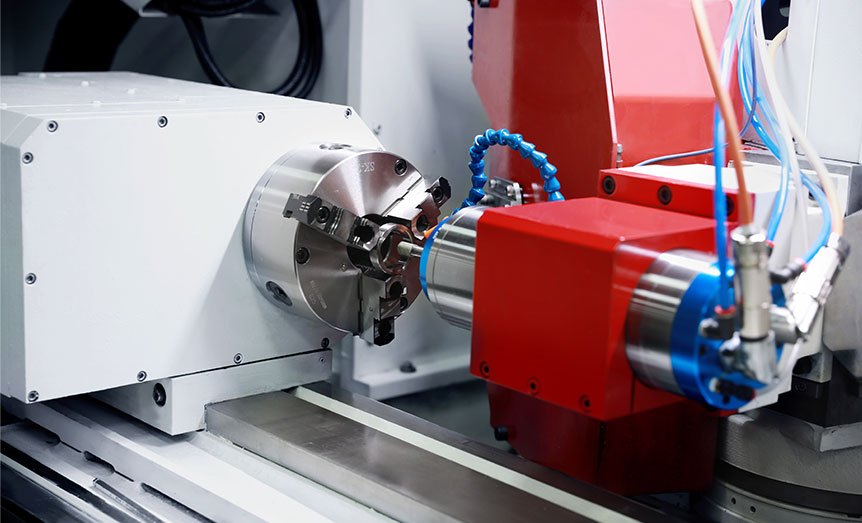

- Workhead: Utilizes a FANUC servo motor for high torque and stability.

- Power Transmission: Features precision ballscrew with servo motor drive and HEIDENHAIN linear encoder for improved axial motion positioning accuracy.

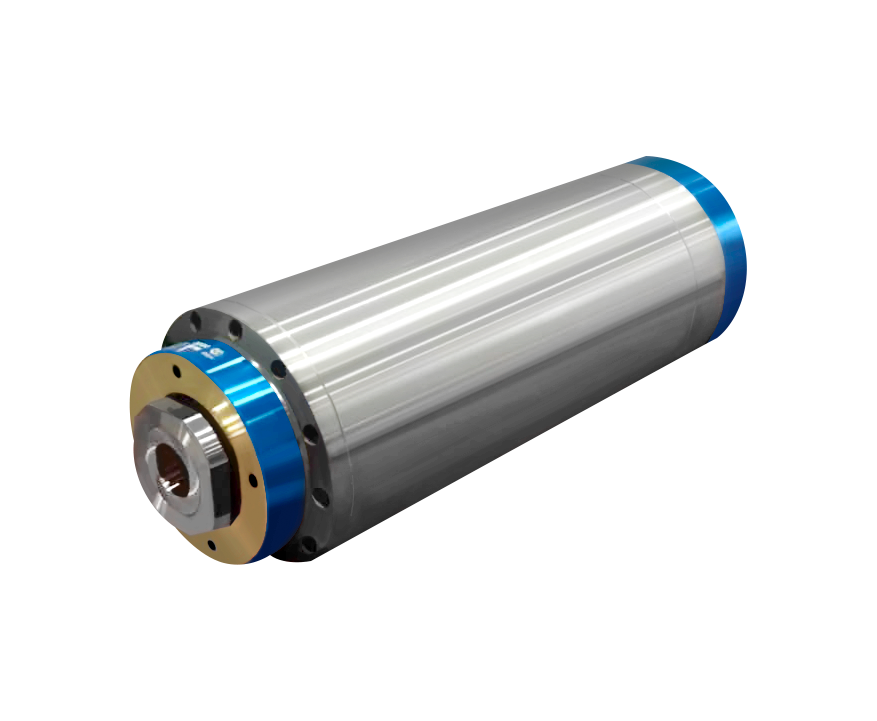

- Grinding Wheel: Built-in spindle with high rigidity and torque, customizable to customer needs of the degree of wheel head within a temperature range of -10°C to 240°C.

Machine Spectification

| Type | Unit | ||

|---|---|---|---|

| Distance between Center | mm | 1000 / 650 / 400 | |

| Grinding Length | mm | 1000 / 650 / 400 | |

| Center Height | mm | 175 | |

| Maximum Workpiece Weight | kg | 150 / 80 | |

| Cross Slide: X-axis | |||

| Maximum Travel | mm | 275 / 250 | |

| Speed | mm/min | 0.001~10000 | |

| Longitudinal Slide: Z-axis | |||

| Maximum Travel | mm | 1150 / 880 / 620 | |

| Speed | mm/min | 0.001~10000 | |

| Wheelhead Assembly | Fixed Wheelhead | Turret Wheelhead | |

| Rotation Range | 0° / 15 °/ 30° | -10°~240° | |

| Direct Drive Power | kw | Up to11 | |

| Grinding Wheel Specification | mm | 500 * 60 * 203 | |

| Grinding Wheel Linear Speed | m/s | 60 | |

| Diameter of Internal Grinding Spindle Hole | mm | 120 | |

| Driving Power | kw | 15 | |

| Spindle Rotation Speed | rpm | 8,000~30,000 | |

| Workhead | |||

| Speed Range | rpm | 1~1000 | |

| Drive Power (Fanuc) | kw | 1.8 / 1.2 | |

| Grinding Roundness Accuracy | mm | < 0.0008 | |

| Assembly Taper | MT4 / MT5 | ||

| Tailstock | |||

| Matching Taper Hole | MT3 / MT4 | ||

| Sleeve Travel | mm | 35 (1.37”) | |

| Sleeve Diameter | mm | 50 | |

| Grinding Taper Precision Fine Adjustment | µm | ±20 | |

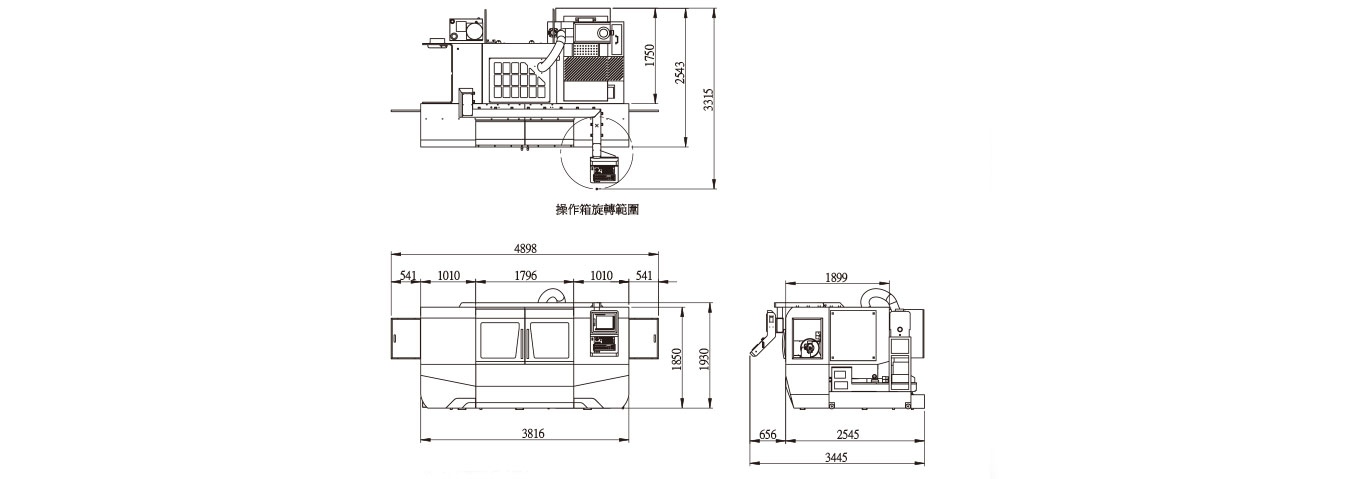

Machine Dimension

*Drawing Unit : mm