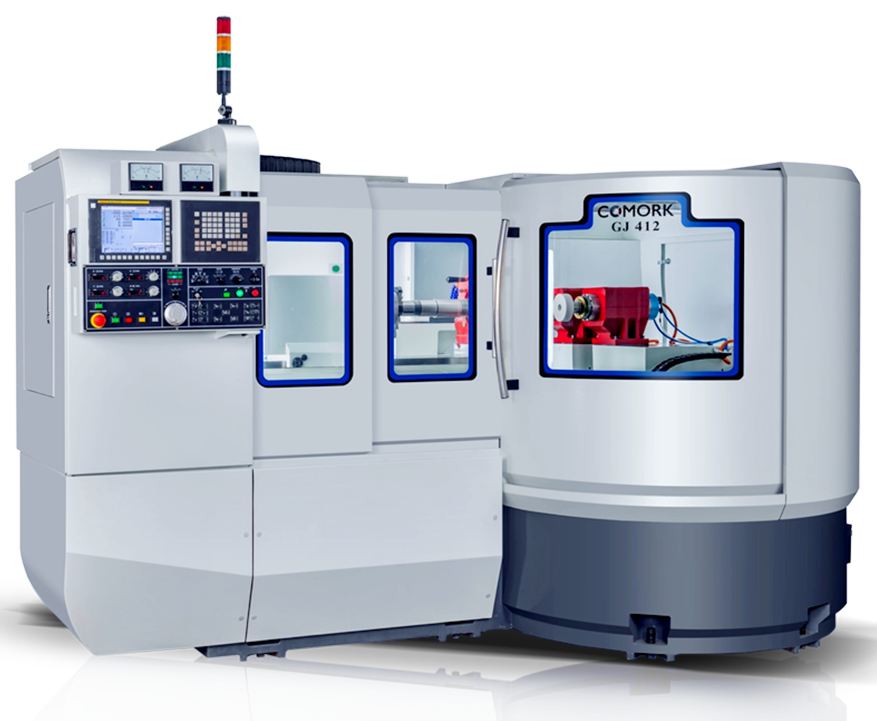

CNC External/Internal Grinding Machine Feature

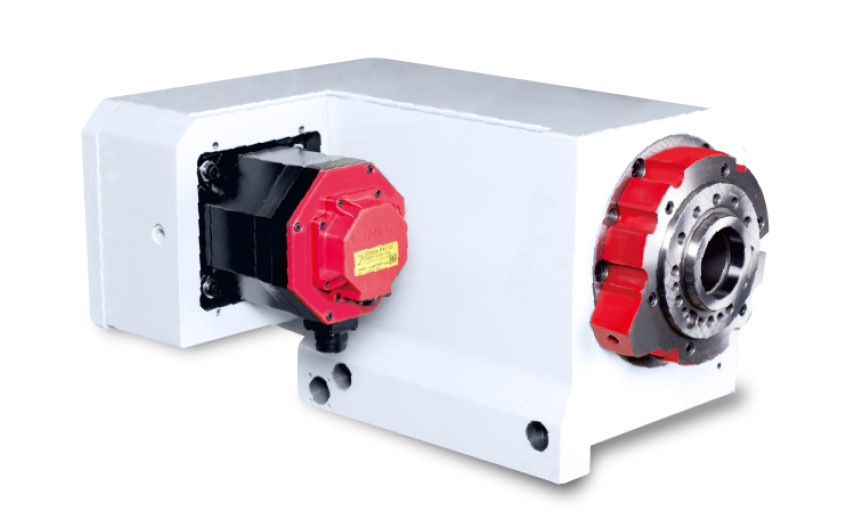

- Are available to choose various rotation speed spindles, to reach the highest grinding efficiency.

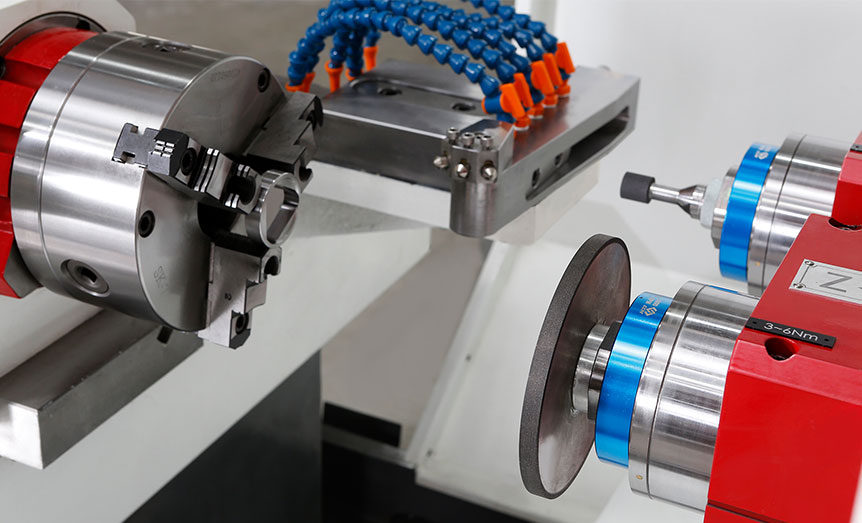

- Dual grinding spindle which is capable to grind inner/outer diameter and end face in one process.

- ID, OD, end face and bevel grinding once for all.

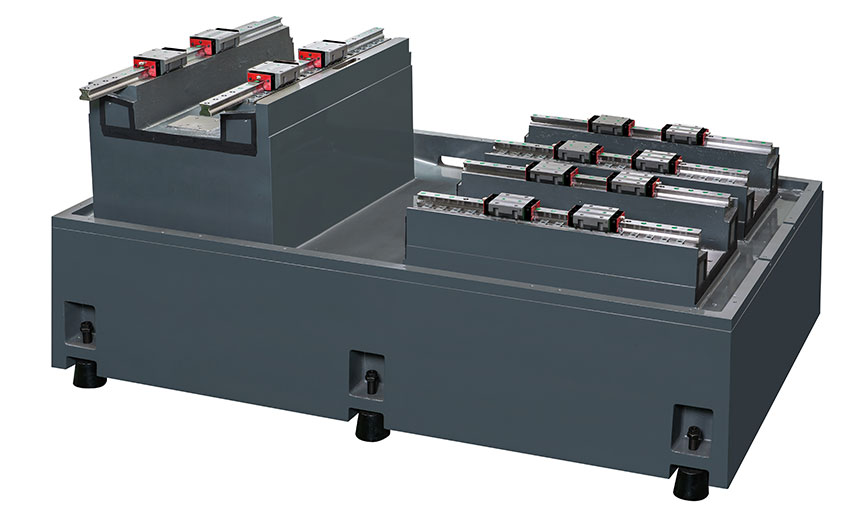

- High rigidity structure, to make sure the best grinding stability.

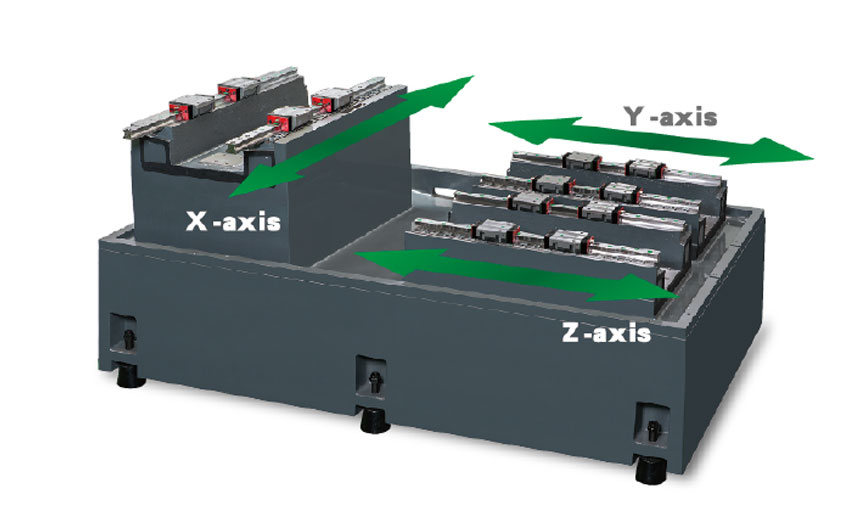

- X, Y, Z axis both mount high degree of precision linear guide.

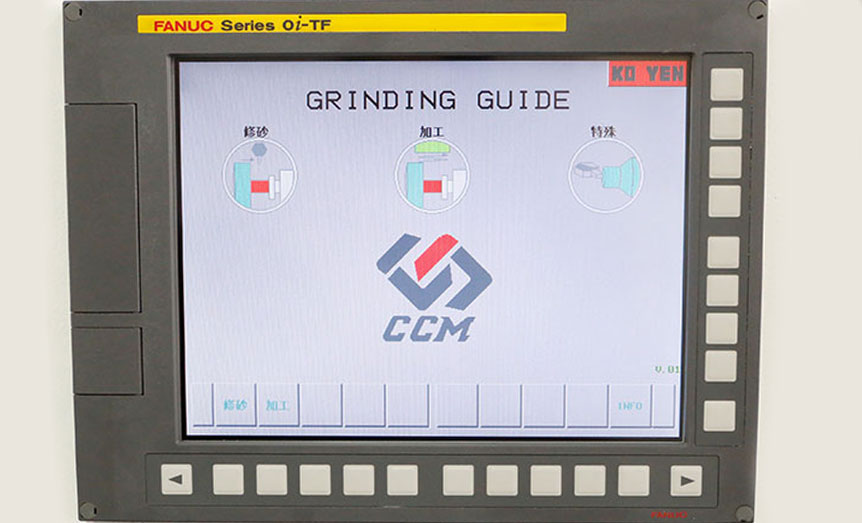

- This machine equip FANUC Oi-TF controller.

- Only need clamp one time, can finish multifaceted processing.

- Non-circular grinding function.(option installation)

- Totally-enclosed casing.

Machine Specification

| Type | GJ-400A | GJ-400B |

|---|---|---|

| Max. Workpiece Diameter | Ø 400 mm | Ø 400 mm |

| Workhead Revolve Speed | 0 ~ 1,000 rpm | 0 ~ 1,000 rpm |

| Spindle Plane Manual Angle Adjust | +15˚ & -2˚ | +15˚ & -2˚ |

| Max Travel : X axis | 360 mm | 360 mm |

| Max Travel: Y / Z axis | 340 + 240 mm | 340 + 240 mm |

| ID Processing Scope | Ø 0 ~ 310 mm | Ø 0 ~ 310 mm |

| OD Processing Scope | 380 mm x 100 mm | 380 mm x 100 mm |

| Length Processing Scope(ID) | 250 mm | 250 mm |

| Max. Workpiece Weight | 56 kg | 56 kg |

| X / Y / Z Axis Travel Speed | 0 ~ 10,000 mm / min | 0 ~ 10,000 mm / min |

| Axis Travel Unit | 0.001 mm | 0.001 mm |

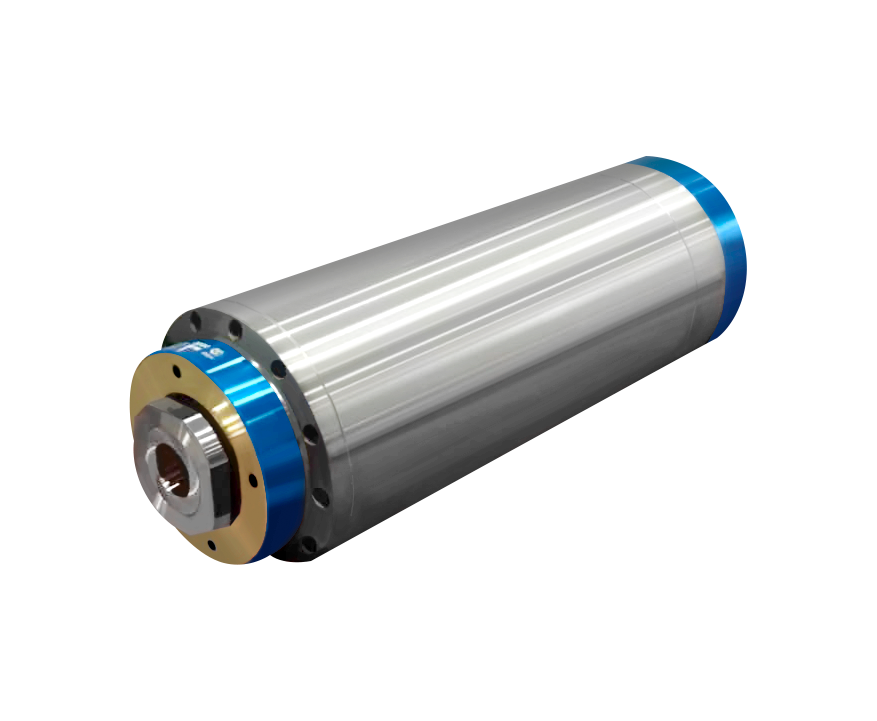

| Spindle Motor Type | 3HP 2kw 2P |

AIF8 / 3,000 1.6 kw Wheel head A-5 |

| Spindle Rotation Speed | 8,000 ~ 50,000 rpm | 8,000 ~ 50,000 rpm |

| Power Demand | 15 kw | 15 kw |

| Machine Net Weight | 4,500 kg | 4,500 kg |

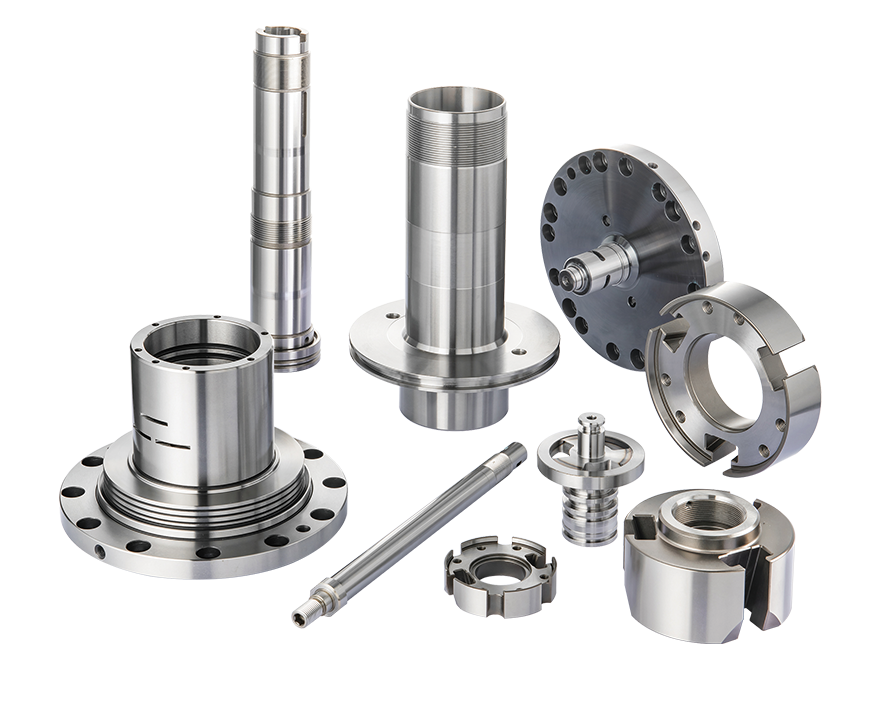

Industry of Application

-

Part of Machine Spindle

-

Vehicle Transmitting Gear

-

Mold Manufacturing

-

Medical Instrument

-

Aerospace Industry

Multifaceted processing, Once and For All

Take controller special software of design,to grinding complex workpiece and multifaceted processing can do once for all.

Make sure of high efficiency and high degree of precision,both lower the cost of manufacturing.

Make sure of high efficiency and high degree of precision,both lower the cost of manufacturing.

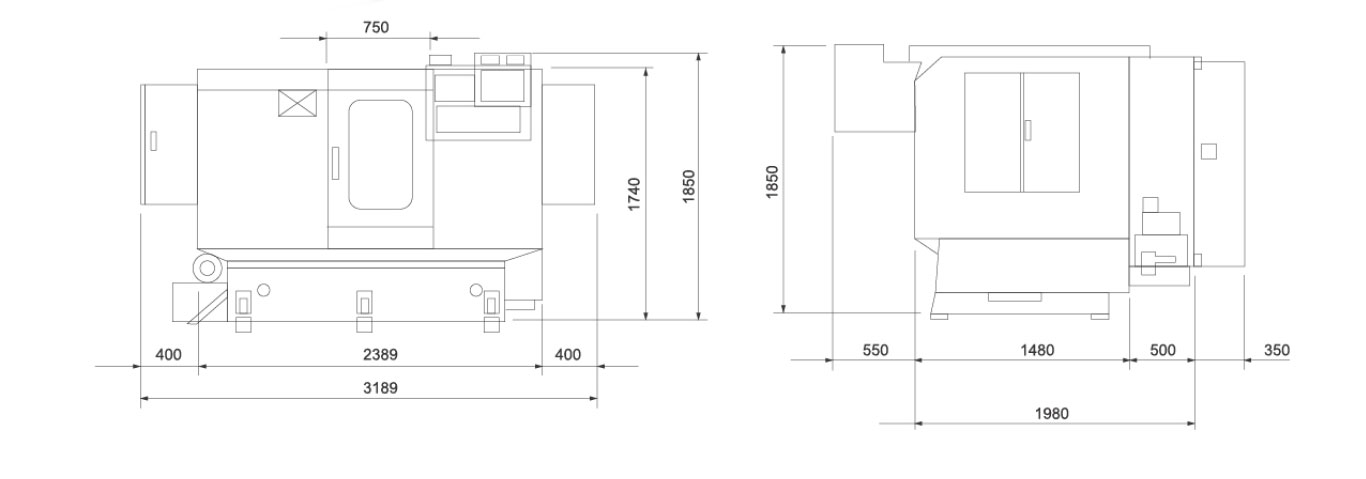

Machine Dimension

*Drawing Unit : mm